Subscribe

Price : $350

Start Date : 04/01/2016

End Date : 04/07/2016

Author : Saqib Maqbool

Tecwallet Funds available: $0

LogIn Forgot password? Create account

OR

Course Description

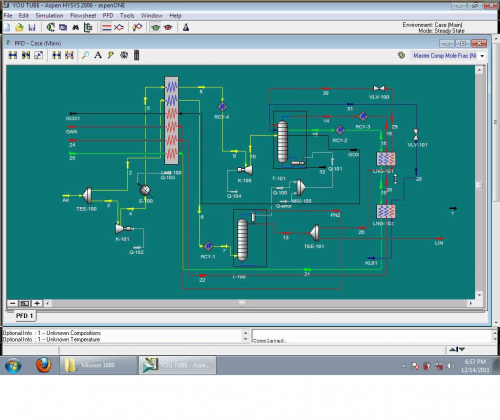

Learn to build, navigate and optimize process simulations using Aspen HYSYS. Learn to evaluate the performance of existing equipment, improve the convergence performance of a simulation; troubleshoot common issues. Model unit operations such as distillation columns, heat exchangers, separators and rotating equipment. Learn how to use Oil Characterization for crude assays. Learn how to perform Case Studies to determine the optimum operating point for a process. Learn how to use the pipeline hydraulics capabilities. • Learn to build, navigate and optimize process simulations using Aspen HYSYS • Learn efficient use of different HYSYS functions to build steady state process simulations

Course Objective

• Leverage the intuitive solving capabilities and other key features of Aspen HYSYS that allow for rapid flowsheet construction • Use the Workbook and Flowsheet interfaces for quick and effective modeling • Discover how multi-flowsheet integration can streamline and organize simulation efforts • Explore a variety of means of reporting simulation results • Evaluate the performance of existing equipment by leveraging the equipment rating capabilities of Aspen HYSYS • Improve the convergence characteristics of columns and flowsheets; troubleshoot common problems • Perform Case Studies to determine the optimum operating points for a process

Course Certificate

Process & Control Associates certificate will be issued to all attendees upon completion of the course

Who Should attend?

• New engineering graduates/technologists who will be using Aspen HYSYS in their daily work • Process engineers doing process design and optimization projects and studies • Plant engineers checking plant performance under different operating conditions • R&D engineers and researchers using Aspen HYSYS for process synthesis

Course Outline

Aspen HYSYS Process Simulation Overview

• Identify the benefits of process simulation

• Describe the capabilities of Aspen HYSYS

• Introduce the Aspen HYSYS graphical user interface and organizational structure Getting Started

• Enter necessary elements to fully define a Fluid Package • Specify required parameters in order to execute flash calculations and fully define material streams • Modify and set desired units of measure • Review stream analysis options

• Workshop: Introduce basic concepts necessary for creating simulations in Aspen HYSYS Propane Refrigeration Loop

• Add and connect unit operations to build a flowsheet

• Use available tools to manipulate the user interface

• Convert a simulation case to a template

• Workshop: Build and analyze a propane refrigeration loop Refrigerated Gas Plant

• Utilize the Heat Exchanger model in Aspen HYSYS

• Introduce mathematical operations, starting with the Balance and Adjust

• Add a Template file to an existing simulation

• Workshop: Model a simplified version of a refrigerated gas plant and incorporate multiple flowsheet architecture Reporting in Aspen HYSYS • Survey common result reporting techniques in Aspen HYSYS

• Generate Excel reports from the HYSYS Workbook

• Use the Report Manager to create custom unit operation and stream reports

• Discover how to report non-standard physical properties in your material streams

• Introduce Data Tables as an option to create customized simulation results tables

• Provide a brief introduction to Aspen Simulation Workbook, enabling integration between Microsoft Excel and Aspen HYSYS Oil Characterization and HP Separation

• Introduce the Aspen HYSYS Oil Manager and Assay Management features and how they are used for assay characterization

• Perform Spreadsheet calculations in Aspen HYSYS

• Use the Case Study feature to run flowsheet-wide scenarios

Workshop: Use the Assay Management tools to characterize a crude assay, then employ the Spreadsheet and Case Study features to determine how Gas-Oil Ratio (GOR) varies with operating pressure Two Stage Compression

• Introduce the Recycle operation in Aspen HYSYS

• Recognize suitable locations for a Recycle operation

• Enter compressor curves to determine head and efficiency as a function of inlet flow

Workshop: Utilize the Recycle operation to build a two stage compression flowsheet; define and activate compressor curves thus modeling a HYSYS compressor with real-world data Heat Exchanger Rating

• Review the available heat transfer unit operations in Aspen HYSYS

• Compare and contrast the applicability and operation of different heat exchanger models

• Implement Aspen Exchanger Design & Rating (EDR) for rigorous heat exchanger calculations within Aspen HYSYS

• Introduce the Activated Exchanger Analysis feature for continuous heat exchanger study and design

• Workshop: Use a Rating model to determine if an existing heat exchanger will meet desired process specifications; design and rate a heat exchanger using the EDR interface inside Aspen HYSYS Best Practices & Troubleshooting

• Discover Activated Analysis for continuous evaluation of economics, energy usage, equipment design, and dynamic modeling

• Identify best practices for using Aspen HYSYS

• Investigate reasons why a simulation may produce poor results or errors

• Use suggested tips to debug a variety of simulations

• Workshop: Troubleshoot a series of Aspen HYSYS simulations and implement various best practices to get these simulations to solve properly Gas Gathering and Crude Pre-Heat Train

• Use the Pipe Segment operation to model single and multiphase fluid flow

• Introduce Pipe Segment Flow Assurance capabilities to ensure short and long-term viability of pipelines

• Workshop Gas Gathering (O&G Focus): Use the Pipe Segment and its built-in Flow Assurance tools to model and study a piping network in Aspen HYSYS

• Workshop Crude Pre-Heat Train (Refinery Focus): Using a variety of heat transfer, separations, and piping unit operations, construct a raw crude pre-heat train flowsheet NGL Fractionation and Atmospheric Crude Column

• Workshop Atmospheric Crude Column (Refinery Focus): Construct, run, manipulate, and analyze an atmospheric crude distillation column Gas Dehydration and Vacuum Tower & Heat Integration

• Review methods for saturating a hydrocarbon stream with water in Aspen HYSYS

• Use the Hydrate Formation Analysis to calculate hydrate formation temperatures and pressures • Build a vacuum distillation tower with side draws and pump arounds

• Apply the Recycle operation as a flowsheet-building tool appropriate for a variety of simulations

• Workshop Gas Dehydration (O&G Focus): Model a typical gas dehydration unit and study gas saturation, hydrate formation conditions, and unit operation performance throughout the model -

• Workshop Vacuum Tower & Heat Integration (Refinery Focus): Construct and analyze a vacuum distillation tower; simulate heat integration to reduce energy usage within an overall crude processing system

AspenHysys

Comments ( To Post Your Comment Please Login First! )

Start Date:04/01/2016

End Date:04/07/2016

Organiser:

Category: Other

Certification Course